TOSS Alloy-20® Straight and Contour Impulse Heat Seal Band Selection

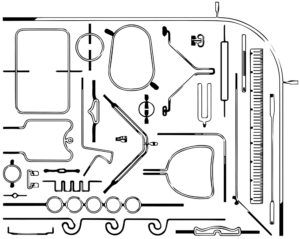

TOSS Alloy-20 impulse heatseal bands are available in over 350 styles, shapes and sizes. Custom designed for any application, new or existing, TOSS Alloy-20 bands are longer lasting and provide for effective sealing at optimum speeds. TOSS’s Norex® impulse heat seal bands are ideal for sealing applications requiring a minimal amount of heat seal band expansion.

Impulse Heat Seal Band Variables

Ideal impulse heat seal band selection is a function of many variables including material composition, material thickness, heat absorption of the jaw, and the nature of the cover strip used over the heat seal band.

In general, the thicker the material to be sealed, the thicker the heat seal band that should be used. Most materials, 1 mil to 6 mil can be sealed efficiently with heat seal band in the thickness range of 0.1 mm to 0.25 mm. With very thick seals (multi-layers to totals of 15 mils or more) it may be well to use thicker bands or consider the possibility of applying heat from both sides.

Custom Contoured Impulse Heat Seal Bands

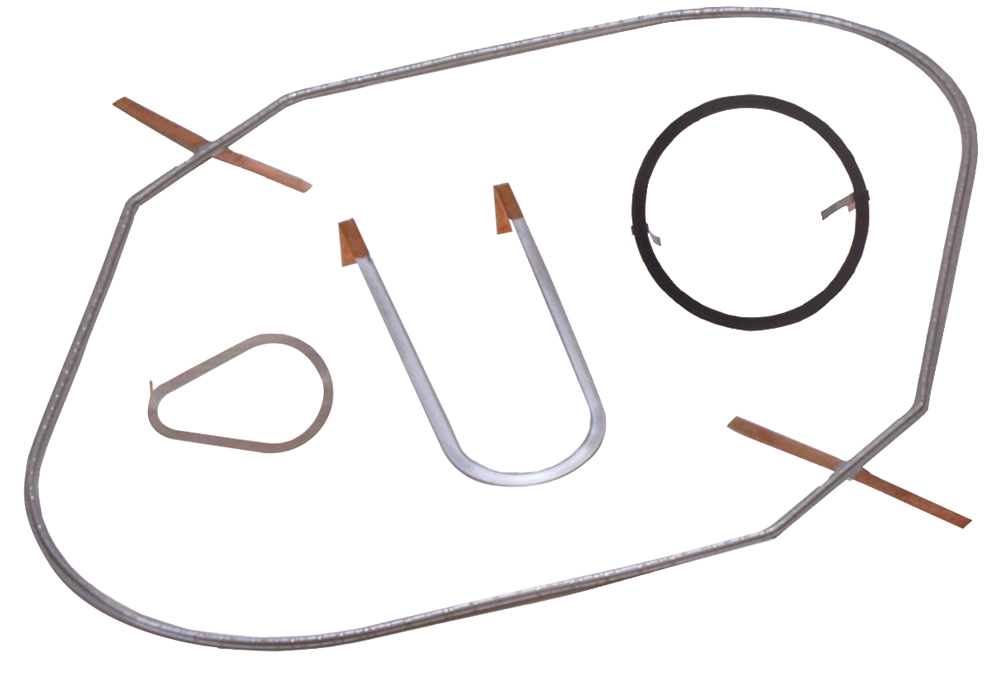

Most believe that impulse heat sealing is limited to straight seams, which is simply not the case. In fact, with TOSS Technology, special shapes can be created to meet your unique sealing needs.

You can design and develop almost any configuration for sealing plastic films and thin thermoplastic parts. Complex shapes with multiple-power feed tabs for equal heat distribution can be developed to meet your needs.

Have TOSS supply your custom contoured heat-sealing elements or engineer your entire heat sealing system.

Plating of TOSS Alloy-20 Impulse Heat Seal Bands

Plated impulse heat seal bands are subjected to both physical and thermal stresses caused by the repeated heating and cooling of the band and attendant expansion and contraction. This condition is exaggerated at or near the ends of the bands.

The "effective" portion of the band (the portion that is in contact with the work piece), will have heat drawn away by virtue of its contact with the relatively cool work piece. Conversely, the portion of the band that is not in contact with the work piece will tend to overheat. If the heatseal band creates a gap between the end of the Jaw Bar and the Jaw End Block, a small portion of the band will get very overheated.

This is a very common occurrence in bands that are not protected by the addition of a copper-plated heat sink at and near the ends of the band. Band breakage most commonly occurs near the end of the band.

Impulse heat seal band replacement and the machine operator’s down time can be substantially reduced by adding copper plating to the end of the band. Further, operating efficiency and band life can be prolonged by adding additional copper on the band that extends at least 0.25" into the "effective" portion of the band.

Heat Seal Band Cross-Sections

Selection of the best Heatseal Band for any given application involves several considerations. The band must be of the correct width and configuration to produce the desired seal or cut/seal. In addition, the band must be thick enough (have sufficient mass) to store the heat energy required for delivery to the material being sealed.

When creating an impulse seal, it is desirable to terminate the heating cycle as soon as possible and begin cooling. Remember, the seal is not finally made until the seal area is cool enough to be dimensionally stable. If the Heatseal Band is too thick or the heat energy delivered is too great, the cooling time will be prolonged, thus prolonging the total cycle and limiting production rate.