PIREG®-C2-220 In-Cabinet Impulse Heat Seal Controller

The PIREG-C2-220 is an In-Cabinet Impulse Heat Seal Controller ENET, Din-Rail mounted with temperature ranges up to 500°C depending on the unit and voltage ratings of 115, 230, and 400 VAC. This controller is specifically built with the high response and precise control needed for sealing the wide variety of polymeric films used in contemporary packaging.

Description of the Controller

The PIREG C2 series controllers are designed for convenient in-cabinet Din-Rail mounting, with temperature ranges up to 500˚C depending on the unit, and voltage ratings of 115, 230, and 400 VAC. The PIREG-C2-200 features extremely precise and fast-measuring technology, essential for accurately determining and controlling the temperature of a heat-sealing band. Unlike traditional methods that use thermocouples, the PIREG temperature controller measures the band voltage and current, repeating this measurement fifty to sixty times per second.

Using these voltage and current values, the actual temperature is calculated from the heat sealing band's resistance. If the measured values deviate from the set point, the transformer's primary voltage is adjusted by phase-angle control, altering the current through the heat seal band and thus changing its temperature. The PIREG temperature controller measures and evaluates this change, adjusting the temperature as needed. This rapid and precise adjustment eliminates the need for slow-to-respond temperature sensors like PT100.

The PIREG-C2-200 controller is specifically built for the high response and precise control required for sealing the wide variety of polymeric films used in contemporary packaging. Its precise control ensures easy validation, maintaining consistent sealing cycles minute to minute, day to day, and year to year. The high response allows more cycles per minute, as the heatseal band can be energized and reach the exact sealing temperature before the jaw bars close. This precise control eliminates temperature overshoot, extends the heatseal band life, and helps preserve the anti-stick cover strips.

Precise Control via an EtherNet/IP™ Interface

The PIREG-C2-220 Ethernet/IP interface can be used to control all the controller functions and poll controller information. The ACTUAL temperature of the heat seal band is supplied to the EtherNet/IP interface or an analog 0 to 10V DC output. The heat seal band temperature can thus be displayed on an HMI. To increase operational safety and interference immunity, all interface signals are electrically isolated from the controller and the heating circuit.

The controller can be adapted to different heat sealing band alloys (TOSS Alloy-20®, NOREX®, etc.) and set to the required temperature range (0... 300°C, 0... 500°C etc.) via digital interface commands. For assistance with configuring your application contact a TOSS Application Engineer. Common applications include:

- Vertical and horizontal form, fill, seal machines

- Pouch, filling, and sealing machines

- Film wrapping machines

- Pouch-making machines

- Group packaging machines

- L-sealers

The use of PIREG temperature controllers results in:

- Repeatable quality of the impulse heat seals under any conditions

- Increased machine capacity

- Extended life of the heatsealing bands and PTFE coatings

- Simple operation and control of the sealing process

PIREG Controller Comparison Chart

In-Cabinet vs Panel Mounted – Which "Plug and Play" PIREG controller is right for you?

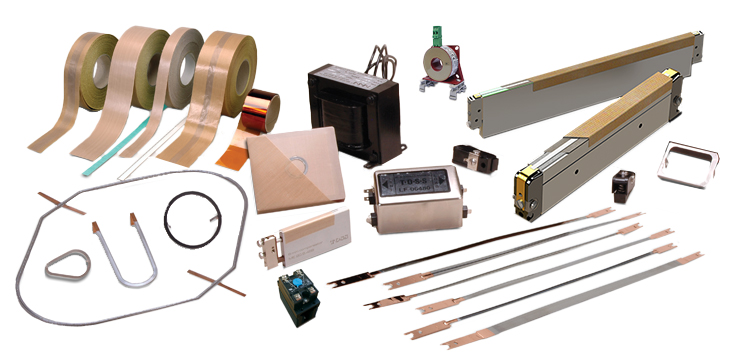

Complete Selection of Accessories and Components

A wide range of compatible accessories and peripheral devices are available for the PIREG temperature controllers. They allow it to be optimally adapted to your specific heatsealing application and to your plant's design and operating philosophy.